An Affordable Prosthetic Hand for Global Change

Steven Reimer M.S. ’24 stepped back from the table after placing the final sensor on the patient’s arm. Two years of hard work had led to this moment. He had traveled 8,000 miles to Jaipur, India to perform the final test of the prosthetic hand he developed as a graduate student in the Robotic Systems Lab at Santa Clara University.

Reimer watched carefully as his patient, a young man named Mohammad, subtly flexed the muscles in his forearm. The plastic fingers on the prosthetic hand clasped a glass jar and moved it flawlessly across the table. What seemed like magic was actually a result of Reimer’s expertise.

“The sensors that I placed on his muscle are connected to a microcontroller in the hand,” Reimer explains. “When the muscle contracts, the sensor detects an electrical signal that drives the hand open or closed.”

His journey to India started during his last year of college when he joined an ongoing project between the School of Engineering and BMVSS Jaipurfoot. The partnership, which was started in 2018 by Professor Chris Kitts, is dedicated to developing a low-cost prosthetic hand to improve the lives of amputees in India.

The most basic mechanized limb typically costs a few thousand dollars. The price can soar to the tens of thousands or more, depending on cosmetic customization and electronic technology.

While working on projects in the Robotics Systems Lab, students are encouraged by Kitts to prioritize the user experience in their design process. It’s not enough to make something cool or technologically advanced. Their creations have to meet the needs of the customer.

“We want to not only build the prosthetics, but also facilitate the process to produce them with some level of cost-effectiveness,” says Kitts, who is also the director of the lab.

In this case, BMVSS Jaipurfoot didn’t just need a prosthetic hand with a price point under $500. They required one that was lightweight, realistic, and equipped with a long-lasting battery.

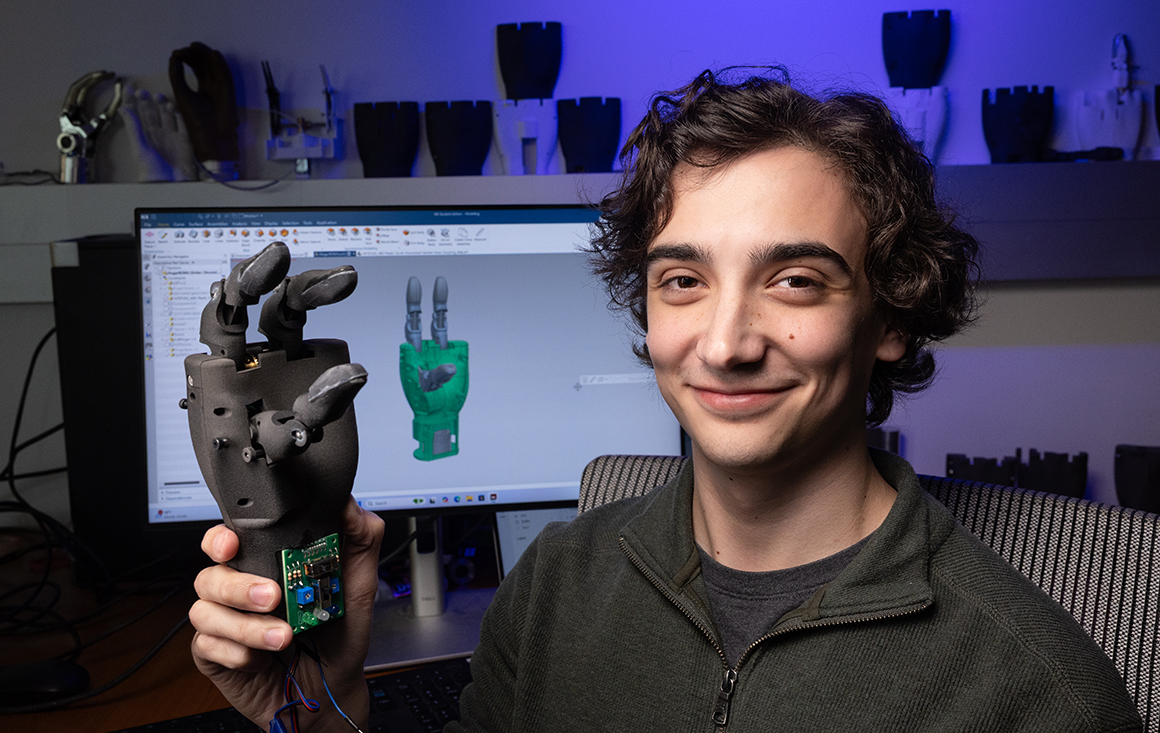

Reimer designed his model with parts that only cost $300, nearly cutting BMVSS Jaipurfoot’s price requirement in half. The organization plans to manufacture hundreds of these prosthetic hands, with the goal of giving them to amputees for free.

Steven Reimer ’24 considered different designs to make his model look as realistic as possible. | Photo by Jim Gensheimer

Since there was already a working model constructed by past teams of Santa Clara students, Reimer’s task, at least initially, was minimal. He was asked to reduce the number of wires on the inside of the hand to make it compatible with a faux arm socket already in use by BMVSS Jaipurfoot. However, once he got started, he ended up fully redesigning the prosthetic with more affordable materials to help the organization fulfill its philanthropic efforts.

Reimer spent 10 days in India testing his design with three amputees. He had several backup methods prepared, including one that used a shoulder-shrug sensor to activate the hand. Ultimately, the muscle-activated design worked on the first try, so he didn’t have to use any of the other options. The patients provided Reimer with valuable feedback, including suggestions about how to improve the hand’s durability.

“It was a really good learning experience for Steven,” says Kitts. “The next phase is to make updates to the hand and design the manufacturing process. If it’s successful, it would be a Santa Clara design.”

The RSL conducts a world-class field robotics program in which interdisciplinary teams of students develop and deploy advanced robotic systems and autonomous control technology missions on the land and in the air, sea, and space.